One city's trash is a pair of tech companies' treasure.

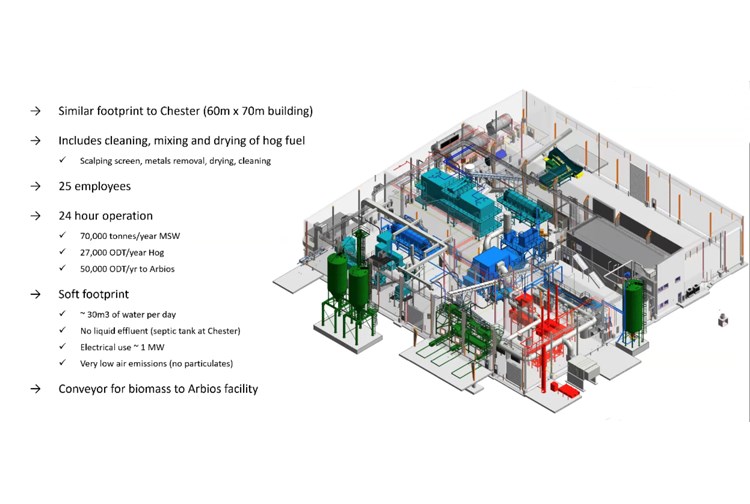

Sustane Technologies Inc. and Arbios Biotech – a joint venture between Canfor and Australian tech company Licella – are looking to build a pair of plants in the area of Canfor's Intercontinental and Prince George pulp mills. Sustane's facility would process roughly 70,000 tonnes of municipal garbage and 27,000 tonnes of hog fuel from Canfor's operations to produce biomass pellets, which Arbios' plant would then convert into biofuel.

When fully complete, the operations are expected to create 175 direct jobs, and roughly 600 jobs indirectly.

On Thursday, Sustane president Peter Vinall told the Regional District of Fraser-Fort George's environment and parks standing committee that his company's process can divert approximately 90 per cent of the material currently going to the Foothills Boulevard Regional Landfill.

"We take regular, landfill-destined solid waste, after recycling separation. (And) we can do this at a cost lower than landfills," Vinall said. "We believe the potential here is to make this region a waste diversion leader in British Columbia, and the world."

The Canadian tech start-up opened its first commercial plant in Chester, N.S. last year and has proven the technology works, he said.

Municipal garbage would be trucked to the plant, where it would be shredded, heated in a sealed vessel and separated into different materials, he explained.

Roughly half the material that ends up in landfills is biomass like paper, food waste and cardboard, Vinall said. That material is converted into biomass pellets, which can be burned like wood pellets.

However, the proposal would see the Sustane plant produce roughly 50,000 tonnes of pellets which would be sent by conveyer belt to Arbios Biotech's facility to be converted into low-carbon liquid biofuels using Licella's proprietary technology.

Another significant contributor to landfill waste is low-grade, single-use plastics like plastic bags, wrapping material, etc.

"By separating the plastic away, you can make fuel... that is clean enough to use in regular processes," Vinall said. "Our process is 100 per cent energy self-sufficient. About a quarter of the energy in the plastic will run the plant."

In addition to synthetic diesel fuel, the plastic waste can be used to produce naphtha – a chemical used in plastic production, he said.

Material like metals and higher-grade plastics are removed for recycling, and glass is crushed into a sandy aggregate material, he said.

"The mantra here is nothing goes to waste," he said. "Our goal is to find a useful outlet for the glass aggregate material."

The plant won't eliminate the need for a landfill, but it can reduce the amount of material ending up there, he said. In addition, the plant would create about 25 full-time jobs and would reduce greenhouse gas emissions by the equivalent of nearly 100,700 tonnes of carbon dioxide per year.

Vinall said the plant will have a minimal ecological impact, producing no liquid effluent and very little air pollution.

The project is not contingent on government funding or support, he said. However, the company would look to charge a tipping fee for trash, at a rate lower than the landfill.

"We'll be looking for a long-term, 20 years for example, agreement for a supply of solid waste," Vinall said.

CANFOR PARTNERSHIP

Canfor Pulp CFO and executive vice president Alan Nicholl said his company is expecting to make a final investment decision on the project by the third quarter of the year. If the project is approved by the board, construction of the first phase of Arbios' biofuel plant could begin this year, with the goal of having the first phase operational by late in 2022.

"We've estimated roughly 150 direct jobs," Nicholl said. "(But) that's at full capacity, and we believe it will take awhile to get to that. The first plant will be relatively small in size."

According to Arbios' website, the company is currently building a small facility to process 5,000 tonnes per year of post-consumer biomass to produce 10,000 barrels a year of biocrude fuel.

Once fully complete, the Arbios facility in Prince George would handle 10 times as much input material.

Licella's technology uses biomass to produce biofuel with a carbon intensity 70 to 80 per cent lower than fossil fuel-based gasoline or diesel, Nicholl said.

Carbon credits and other environmental incentives are part of the economic model for the plant, he said.

"Our target is to find high-value and low-carbon solutions," he said. "We're motivated to have as low a carbon footprint as possible."

BOARD SUPPORT

The members of the regional district's environment and parks standing committee approved a motion, calling for the regional district's staff to work with the companies on the proposed project – providing information about the waste ending up in the Foothills landfill and what a potential agreement would look like.

Prince George Mayor Lyn Hall encouraged the partners to bring their presentation to city council as well.

"This is exactly what we need," Hall said. "This is the move-forward opportunity for us, when it comes to solid waste management."

.png;w=120;h=80;mode=crop)