Radiation treatment for some patients with facial cancer is becoming less stressful, thanks to a unique partnership between the BC Cancer Agency of the North and the Two Rivers Gallery.

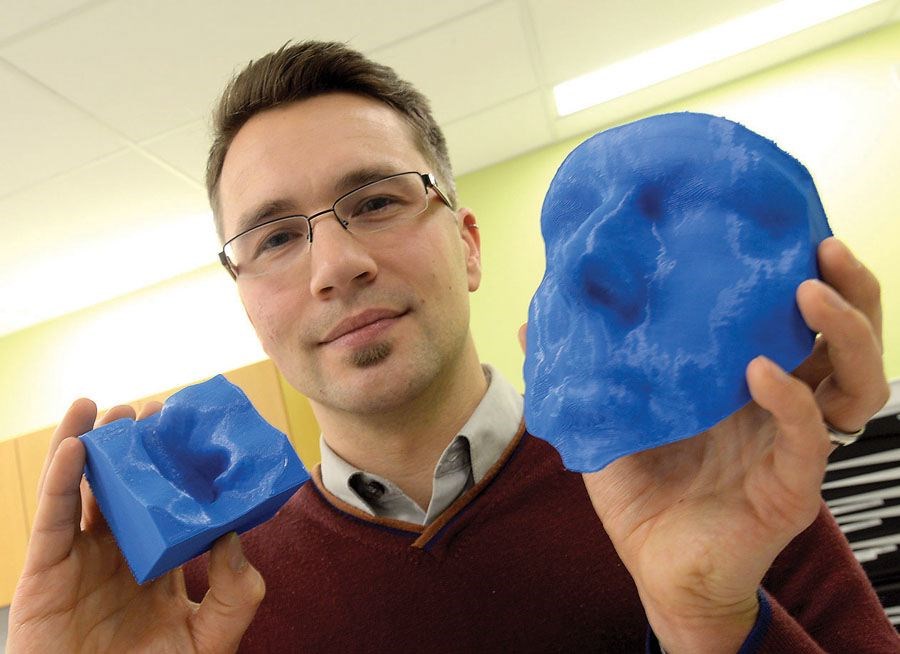

Medical staff have begun using the gallery's 3D printer to create moulds for boluses, which are used to ensure patients are receiving the proper dose of radiation when a tumour is near the skin's surface.

When medical physicist Piotr Dubrowksi heard the gallery had acquired one of the specialized printers, he quickly realized it could benefit patient care. Without the technology, patients must come in for a time consuming - and sometimes painful - process of creating a facial mould by hand.

"For patients who have a lot of superficial pain or who have a lot of anxiety and claustrophobia, this is a huge source of anxiety and pain for them," Dubrowksi said.

But when a 3D printer is used, the patient just needs to have a quick computerized scan done of their face and the printer does the rest of the work. Depending on the size of the mould, it can take anywhere from four to 12 hours to print.

Once the mould is created, staff use that to make a bolus, which is put on top of the affected area before a patient receives radiation treatment. Boluses are used for tumours close to the surface of the skin because a typical radiation beam spares the first few millimetres of skin.

"If you have a tumour right at the surface, you will never be able to achieve dose right to that surface so you need to put something on top of that surface in order to bring the dose at the skin's surface up to a clinical dose," Dubrowksi explained.

For most tumours at the surface of the body, a rubbery substance can be placed on top of the affected area to allow for proper treatment, but when it comes to facial areas around the nose, ears or eyes the body's topography is too complex and a mould is required to create a bolus that will conform with all the curvatures of the body.

So far only one patient has been scanned for the mould, but Dubrowksi said it was a first in B.C.

Having the technology available in the north is particularly important, according to Dubrowksi, because of the long distances some patients come for care. The 3D printer can save some patients an entire trip to Prince George.

"We can do this [facial scan] at the start when we first see them and then we'll be ready for when they come for treatment," Dubrowksi said.

Now that the technology has been successfully used, Dubrowksi estimates that about 10 to 12 patients a year at the cancer agency's Prince George site could make use of the 3D printer.

Two Rivers was more than happy to oblige when Dubrowksi first asked for their help.

"That's what the [3D printer] MakerLab is all about, getting the people and the community involved and making this resource - along with all the other tools we have - open for everyone and seeing what they can do with it," gallery public programs manager Carolyn Holmes said.

The gallery has been involved with healthcare delivery in the past, but never on the clinical side of things.

"We go into adult psych and youth detox and pediatrics and do art with the patients," Holmes said. "We know that art can be used to help people as they're going through an illness or if they're dealing with an addiction, but I don't think we ever thought we could help create something that would help with the clinical treatment of a patient."

The cancer agency is looking at buying its own 3D printer, which would be located in the Lower Mainland so that other patients in B.C. can benefit from this and other uses of the technology. Dubrowksi said the Prince George site would have access to that machine when it's up and running, but he's hopeful the partnership with Two Rivers will continue because of the proximity of the printer and the short turn-around time.

"This is definitely the wave of the future, whether it's for patients or any of the other associated tasks with the clinic, we're so technology-driven and often we have to figure out ways to do things very quickly, very precisely and on the fly," he said.

Other individuals and groups have also been using the MakerLab for their purposes. For instance StartUp Prince George and the Woodturners Guild each come to the lab once a month and other people who have an interest in the technology have formed their own group to explore the printer's capabilities.

The lab is open to the public every Thursday from 5 p.m. to 9 p.m. People can bring their own materials or work on projects already on the go at the gallery.